Picked up my first Sunbeam over the winter, a 1966 SV for my wife. Since not long after we got it, the temp gauge would occasionally read a bit high at speed on longer trips. Nothing extreme, but definitely a bit abnormal. I was suspecting a sticking thermostat or malfunctioning sending unit. In any case, my wife got the idea that the gauge was broken, and ignored it while driving home from work on a warm day. She got home complaining the car kept dying at stop signs and downshifting, so went out and jumped in the car. It fired right up, but the temp gauge was pegged full hot. Pulled it the 15' into the garage and shut it down. Turns out, she had driven it that way for 15-20 miles on the highway

Long story short, replaced the thermostat the next morning hoping that was it. Tested the old one in a pan of water on the stove, it appeared to open fully as it should. The car was down roughly 3/4 of a gallon on coolant. Put in new T-stat since I already bought it, topped up, and crossed my fingers. Car wouldn't start. It has always started. Worse, it didn't sound like it was trying. It would weakly pop on one cyl, then be dead until that one came up again. Crap. Out comes the compression gauge, 30-100-30-30. Guess that explains that! Unfortunately, I didn't check the compression on the car when we bought it (before we bought it would have been smart!) so I don't know how healthy it was before. It ran well so I guess I didn't worry about it. In any case, obviously it was quite a lot better than it is now.

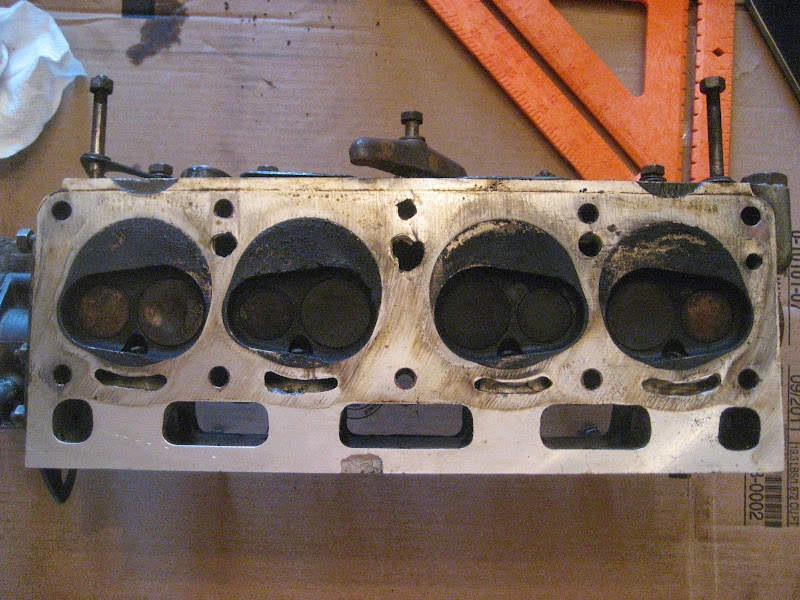

So, I've pulled the head, there was a REALLY thick copper head gasket on the engine. My plan is to take it to a machine shop and have them see if it is warped, and re-plane it as needed. It is not visibly warped, and there are wear indicators left on both sides, so I hope the head can be saved.

Backstory out of the way, I have a couple questions.

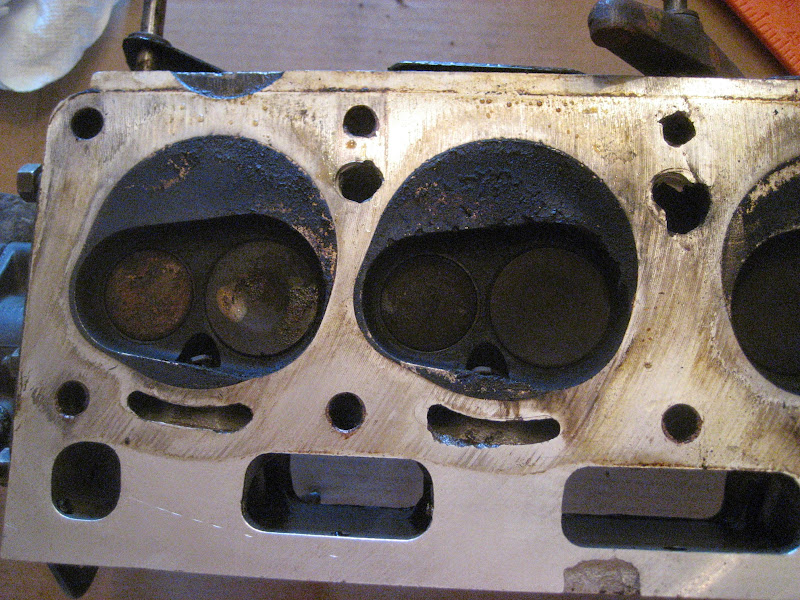

There are a few places that appear to be damaged in the center passages. All the pictures I can find online of Alpine heads these are clean edged, so clearly this is not a normal side effect of casting. Is this damage typical? and what are the likely causes? Is it even a problem?

Looking at the coolant passages, there seems to be some material missing especially on the two nearest the thermostat housing. Was this due to corrosion? Does the current condition necessitate a repair?

Just looking for a general idea of how to proceed here, dealing with this kind of thing is new to me.

Also, what should I get for a new head gasket, any retailers to gravitate towards or avoid? I want to replace the tappet gasket, valve cover gasket, and thermostat gaskets too while I have it apart I would imagine.

Many Thanks,

Nathan

Long story short, replaced the thermostat the next morning hoping that was it. Tested the old one in a pan of water on the stove, it appeared to open fully as it should. The car was down roughly 3/4 of a gallon on coolant. Put in new T-stat since I already bought it, topped up, and crossed my fingers. Car wouldn't start. It has always started. Worse, it didn't sound like it was trying. It would weakly pop on one cyl, then be dead until that one came up again. Crap. Out comes the compression gauge, 30-100-30-30. Guess that explains that! Unfortunately, I didn't check the compression on the car when we bought it (before we bought it would have been smart!) so I don't know how healthy it was before. It ran well so I guess I didn't worry about it. In any case, obviously it was quite a lot better than it is now.

So, I've pulled the head, there was a REALLY thick copper head gasket on the engine. My plan is to take it to a machine shop and have them see if it is warped, and re-plane it as needed. It is not visibly warped, and there are wear indicators left on both sides, so I hope the head can be saved.

Backstory out of the way, I have a couple questions.

There are a few places that appear to be damaged in the center passages. All the pictures I can find online of Alpine heads these are clean edged, so clearly this is not a normal side effect of casting. Is this damage typical? and what are the likely causes? Is it even a problem?

Looking at the coolant passages, there seems to be some material missing especially on the two nearest the thermostat housing. Was this due to corrosion? Does the current condition necessitate a repair?

Just looking for a general idea of how to proceed here, dealing with this kind of thing is new to me.

Also, what should I get for a new head gasket, any retailers to gravitate towards or avoid? I want to replace the tappet gasket, valve cover gasket, and thermostat gaskets too while I have it apart I would imagine.

Many Thanks,

Nathan

Last edited: