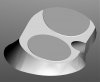

Makes sense to me. I'm not very knowledgeable on interaction of CR, timing, and octane (that's why I tried to maintain stock CR) , but I hope Jarrid (RootesRacer) or someone else chimes in. But it seems to me that doing the Vizard would bring you back quite close to stock CR. And again I caution that the Vizard drawing shows sloped walls, not rounded, so you will only remove a little over 2 cc per chamber. (2.17cc per my calc)

Tom

I would first ask if Stick measured the depth of all 3 wear bars. The photo that sparked the debate looked pretty near the end of the road on one of them. Dont recall which.

WRT the vizard/compression/timing compromise, the stock rootes engine HC alloy engine is what is known in the trades as a knock limited timing motor.

Simply speaking, the timing that is needed for peak torque cannot be delivered across the entire RPM range since the available gasoline detonates becuase of lousy chamber design. The area that is knock limited on these motors is low to mid RPM at full throttle.

The engine would like 34 degrees, but unless you feed it 96+ octane it will knock and break ring lands (why Sticks #2 cyl chamber has dents).

Lowering compression helps reduce the knock threshold and allows added timing without detonation, but there is also typically a .25% loss in torque for each 1% drop in compression due to reduced thermal efficiency.

The Vizard mod helps by taking a thoroughly awful chamber design and makes it less awful. This speeds the flame front propagation, prevents front collisions and allows the engine to make peak torque with less timing, which improves the detonation threshold.

Were it mine, I'd go whole hog and put in flat-top pistons to maximize the benefit of the better chamber, while keeping compression as high as is practical for the fuel available.

If I was on the cheap, I would determine the exact loss of chamber volume on your head and perform a "compromised" vizardectomy so that I got some chamber benefit while keeping the compression ratio stock. This is IMO the only way you will be able to safely run factory timing specs.

The alpine engines were designed to run on higher octane than we have today so many find that a stock motor either needs the best possible gas, or a few degrees taken off the advance.