puff4

Platinum Level Sponsor

Hi, folks -

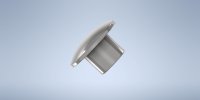

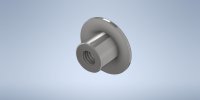

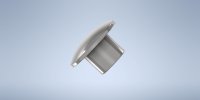

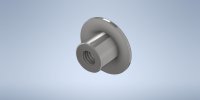

With Warren's generous help, I'm in the midst of creating CAD files for the two different buttons used to hold the latches onto the side windows for Alpine SIII-SV & Tiger hard tops. I believe there are two types - a smaller one and a later larger one. I have samples that Warren sent me, but the larger/later one doesn't have a threaded centre - I'm thinking it must be a repro or something. Anyway, I don't seem to have a later one in my stocks. Can someone please locate one and get me the internal screw dimensions? I need the screw size, thread pitch, and threaded hole depth. (The screw on the smaller one is #10-32, if that helps.)

Thanks!

Here is what I've drawn so far...

With Warren's generous help, I'm in the midst of creating CAD files for the two different buttons used to hold the latches onto the side windows for Alpine SIII-SV & Tiger hard tops. I believe there are two types - a smaller one and a later larger one. I have samples that Warren sent me, but the larger/later one doesn't have a threaded centre - I'm thinking it must be a repro or something. Anyway, I don't seem to have a later one in my stocks. Can someone please locate one and get me the internal screw dimensions? I need the screw size, thread pitch, and threaded hole depth. (The screw on the smaller one is #10-32, if that helps.)

Thanks!

Here is what I've drawn so far...