Knightowl61

Gold Level Sponsor

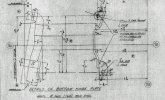

S-III bought without top or windshield. Installed a windshield and aquired a softtop from a S-4 or 5 (b-post hardware included).

Reading https://forum.sunbeamalpine.org/index.php?threads/soft-top-and-hard-top-alignment.30530/#post-224532

Set windshield to 29.5" , moved bottofront window guide fully forward and top guide adjustment didn't do much. The quarter window to frame looked good with windshield at 30".

Even at 30+" the back is way off when the top horizontal frame pin is in the windshield receiver.

The hinge arm won't go forward enough to go into the b-post cap and the back edge of th window is way short at the bottom and still short at the top

Is there a difference in the series III st top frame or b-post linkage? Any ideas on how to put a soft top on this car that fits? ...........Want to go to the invasion.

Reading https://forum.sunbeamalpine.org/index.php?threads/soft-top-and-hard-top-alignment.30530/#post-224532

Set windshield to 29.5" , moved bottofront window guide fully forward and top guide adjustment didn't do much. The quarter window to frame looked good with windshield at 30".

Even at 30+" the back is way off when the top horizontal frame pin is in the windshield receiver.

The hinge arm won't go forward enough to go into the b-post cap and the back edge of th window is way short at the bottom and still short at the top

Is there a difference in the series III st top frame or b-post linkage? Any ideas on how to put a soft top on this car that fits? ...........Want to go to the invasion.