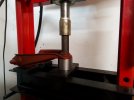

I am halfway thru a Tiger front suspension rebuild, mostlly on weekends last two weeks, 30+ hours a guess so far. What I have at this point is everything ready for re-assasembly, I took everything apart, had everything media blasted, edges deburred, measured, welds to reinforce weak areas, used tap to clean all threads, primmed and painted, fastners inspected (some needing replaced),, cleaned on wire wheel, soaked in EvapoRust (fastners took way more time than I expected and there must be a thousond or more it seemed). At halfway can say it has been mess and time consming for sure. Looking forward to re-assemble with all clean parts so my guess is to have it finished but the end of the month (at least thats the plan). Not difficult, very messy, will take up plenty of garage floor space, will put up a fight, and recommend you seek/find help to press out the A-arm bushings and upper ball joint. FYI I have probably done 5 of these so far in last 40 years and never look forward to doing. The video link in prev post is great.