Nick, How does a vacuum gauge work for this? I've never heard of that technique.

Older engines can't always be tuned or adjusted using the original methods. Harmonic balancers can move, and with today's lower-octane fuels, it's harder to get your old engine to run efficiently without sacrificing performance. A vacuum gauge can help you get maximum performance from your engine, with its individual quirks, using today's fuels.

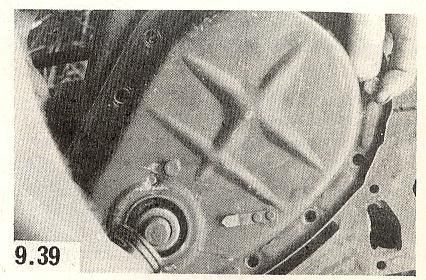

1. Connect a vacuum gauge to a vacuum source directly on the intake manifold (not a

ported vacuum point on the carb.)

2. Disconnect the vac. line to the distributor advance port and plug it.

3. Loosen the bolt securing the distributor so you can turn it to adjust the timing.

4. Start the motor, let it warm up to normal operating temperature, and stabilize at normal hot idle (about 1000 rpm) using the idle speed screw (not the mixture screw).

5. While watching the vacuum gauge, slowly turn the distributor counterclockwise (advance timing) and look for a maximum reading on the gauge. For instance, if the reading on your gauge peaks at 18 inches of vacuum, that is the maximum for your engine. The normal range could be from a high of 20 inches to a low of 16 inches, depending on the internal condition of your motor. (Readings lower than 16 indicate problems). The reading will begin to fluctuate and finally drop when you advance beyond the optimum, so turn the distributor clockwise (retard timing) to go back to the peak, steady, reading.

6. If you are using 100-octane, or higher, fuel you can tighten the distributor knowing that you have the ideal advance for your engine, and the setting and power output the designers intended 50 years ago. (In my state you can use AVGAS [aviation piston-engine fuel] - which is 105-octane low lead - in cars registered as

limited use, antique and classic). You may need to reduce the reading by 1-2 inches total depending on the fuel available in your local area to avoid detonation (pinging).

7. Now set your carb. idle mixture, using the same vacuum gauge and adjusting mixture strength for the highest vacuum reading.

8. Once you have achieved a satisfactory idle mixture, reduce the idle speed to your preference, then remove the vacuum gauge and reconnect the distributor vacuum advance.

Test drive your car and listen for any pinging under heavy acceleration. Additional retarding of the timing may be necessary if excessive pinging occurs, until you may hear a very slight ping under light acceleration, and none under heavy acceleration. Your engine is now optimally timed to run on your available fuel.