ernestovumbles

Gold Level Sponsor

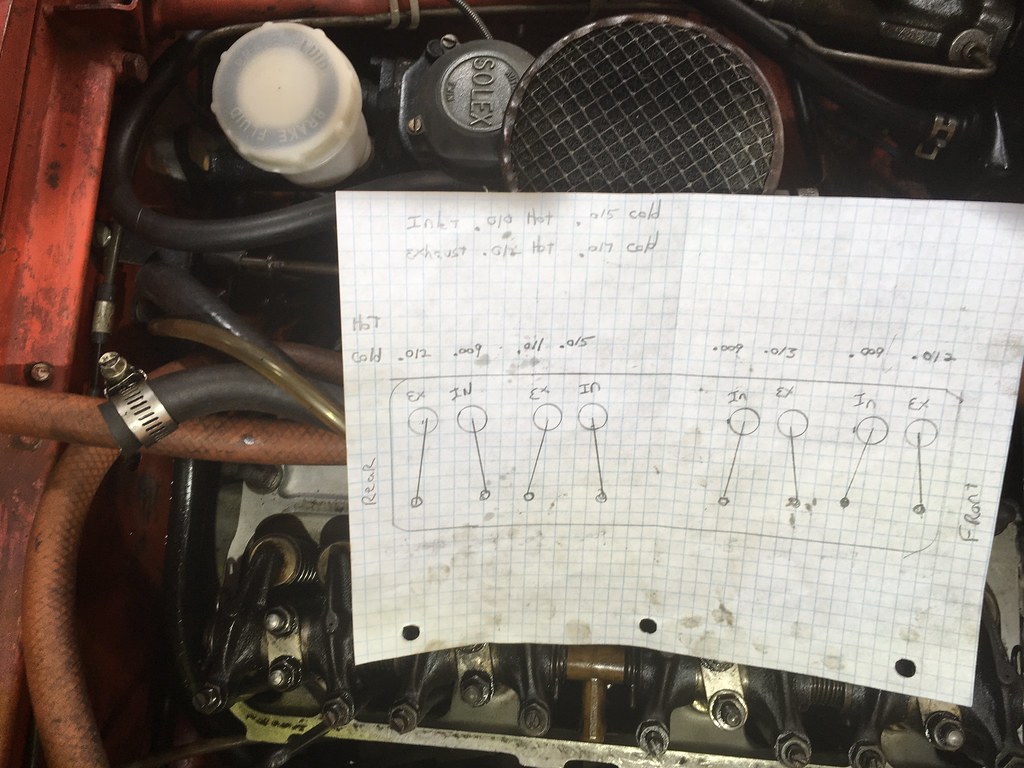

Working on doing my first time valve check/adjustment on my 63 S3 later this week..

I've read thru the forum info, manual and watched the videos, so hopefully I am prepared..

I figure I will measure/check the valves cold first to get some practice before doing it hot.

Right now I am in the middle of cleaning up the valve cover gunk and trying to remove the old hardened cork gasket which has baked itself to the block. Going slow to fit in Sunbeam time between work and real life.

Dont tell my wife I borrowed her toothbrush

I've read thru the forum info, manual and watched the videos, so hopefully I am prepared..

I figure I will measure/check the valves cold first to get some practice before doing it hot.

Right now I am in the middle of cleaning up the valve cover gunk and trying to remove the old hardened cork gasket which has baked itself to the block. Going slow to fit in Sunbeam time between work and real life.

Dont tell my wife I borrowed her toothbrush