-

Welcome to the new SAOCA website. Already a member? Simply click Log In/Sign Up up and to the right and use your same username and password from the old site. If you've forgotten your password, please send an email to membership@sunbeamalpine.org for assistance.

If you're new here, click Log In/Sign Up and enter your information. We'll approve your account as quickly as possible, typically in about 24 hours. If it takes longer, you were probably caught in our spam/scam filter.

Enjoy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum Flywheel?

- Thread starter spmdr

- Start date

jdoclogan

Platinum Level Sponsor

Received the TTV flywheel from UK today. Any thoughts are welcomed for the following lineup and comparisons:

Comparison of the clutch plate side of an 8.5" original and TTV flywheels with original 8" clutch plate

Engine side of flywheel

Closeup of original engine side flywheel

Closeup of TTV engine side flywheel

The ring teeth matched perfectly

The original is slightly higher than TTV flywheel

Comparing original cover pressure plates left to right -

1725 original Alpine 7.5 " with 3 alignment pins and 7.5" clutch plate above

1592 original ??? 8.5" with 3 alignment pins and 8" clutch plate above

1592 original Alpine 8.5" with 2 alignment pins and 8" clutch plate above

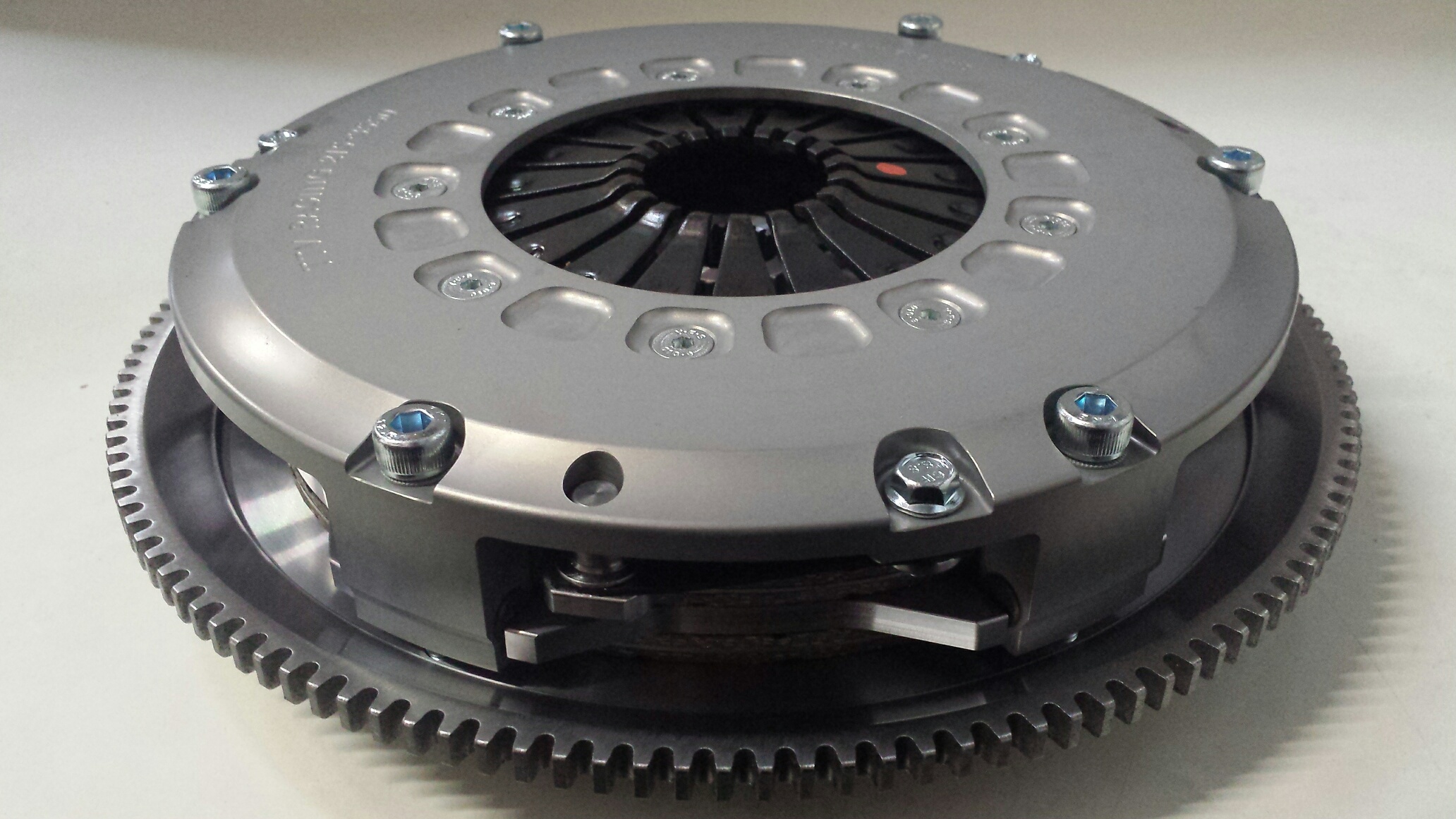

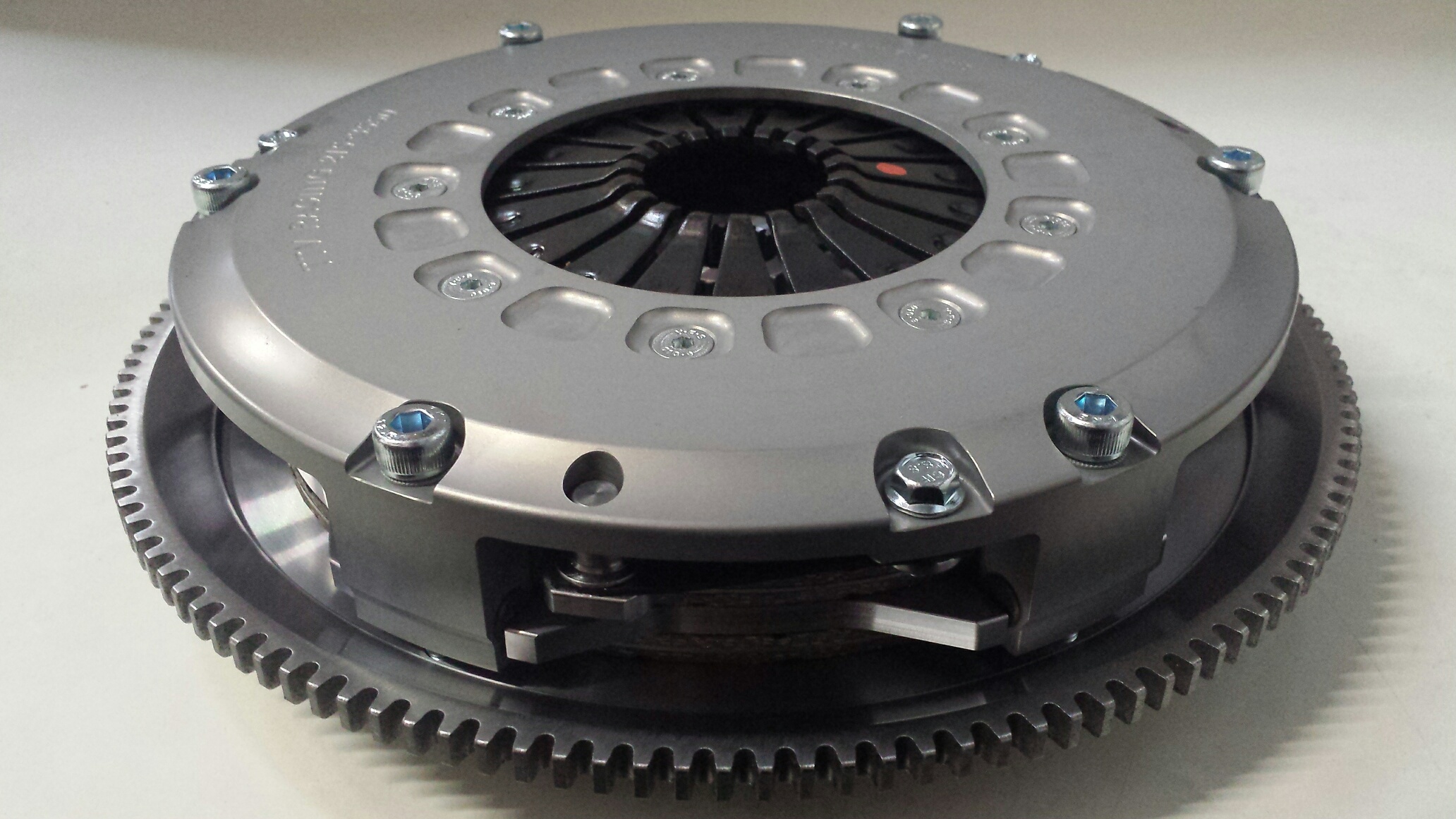

This is a 230mm TTV Organic Fast Road Clutch system suitable for up to 350ftlbs of torque. I'm going to inquire if they have it for a 215mm FW.

Comparison of the clutch plate side of an 8.5" original and TTV flywheels with original 8" clutch plate

Engine side of flywheel

Closeup of original engine side flywheel

Closeup of TTV engine side flywheel

The ring teeth matched perfectly

The original is slightly higher than TTV flywheel

Comparing original cover pressure plates left to right -

1725 original Alpine 7.5 " with 3 alignment pins and 7.5" clutch plate above

1592 original ??? 8.5" with 3 alignment pins and 8" clutch plate above

1592 original Alpine 8.5" with 2 alignment pins and 8" clutch plate above

This is a 230mm TTV Organic Fast Road Clutch system suitable for up to 350ftlbs of torque. I'm going to inquire if they have it for a 215mm FW.

spmdr

Diamond Level Sponsor

I just talked to the local Clutch place about Alpine clutch parts.

He says he has some random stuff but no source of parts.

I'm still thinking about a dual bolt pattern flywheel.

Or maybe even a triple bolt pattern.

I'm wondering what the future of these parts is.

DW

He says he has some random stuff but no source of parts.

I'm still thinking about a dual bolt pattern flywheel.

Or maybe even a triple bolt pattern.

I'm wondering what the future of these parts is.

DW

Last edited:

jdoclogan

Platinum Level Sponsor

Dan, TTV Industrials.com quoted me $950 to the door price on this clutch assembly:http://ttvracing.com/?s=3918+Series+–+215mm+Single+Plate+Track+Day+Clutch+

TTVR Road & Track-day Single Plate 215mm (8.5″)

This clutch assembly will bolt directly onto the lightened flywheel I acquired from them or a standard Alpine flywheel. The problem is making the Series II throw out carbon system (refer to my photos above) work with this.

TTVR Road & Track-day Single Plate 215mm (8.5″)

This clutch assembly will bolt directly onto the lightened flywheel I acquired from them or a standard Alpine flywheel. The problem is making the Series II throw out carbon system (refer to my photos above) work with this.

Last edited:

husky drvr

Platinum Level Sponsor

I'm doing the same. Sachs and TTV racing systems. Even looking at 50s-70s Jeep clutch plates (10 spline - 8.5"). My mind is spinning. Maybe Michael has a solution after he puts out his "work fires."

jdoclogan,

You should investigate the mid 70's Volvo four cylinder clutch assemblies. The disk is 8.5 inches with a 1.0 x 10 hub spline. Don't know if the pressure plate would bolt to an Alpine flywheel, but the release bearing would end up being an issue if it could be installed.

Just a thought.

Have fun,

Don

bernd_st

Bronze Level Sponsor

In order to replace the carbon ring affair something like that could be an option:

https://www.ebay.co.uk/itm/Made-in-...56c9430307:g:ae4AAOSwAB5dXGtQ&redirect=mobile

https://www.ebay.co.uk/itm/Made-in-...56c9430307:g:ae4AAOSwAB5dXGtQ&redirect=mobile

65beam

Donation Time

Is this the release bearing Alpine owners have had problems with or is it a different item?In order to replace the carbon ring affair something like that could be an option:

https://www.ebay.co.uk/itm/Made-in-...56c9430307:g:ae4AAOSwAB5dXGtQ&redirect=mobile

jdoclogan

Platinum Level Sponsor

jdoclogan,

You should investigate the mid 70's Volvo four cylinder clutch assemblies. The disk is 8.5 inches with a 1.0 x 10 hub spline. Don't know if the pressure plate would bolt to an Alpine flywheel, but the release bearing would end up being an issue if it could be installed.

Just a thought.

Have fun,

Don

Thanks Don.

This was from a 2016 posting from George Coleman. Dan I don't know if you investigated all of these possibilities.

I would like to make a note, here is the file for clutch crossovers as you can see all but one listing is for 8' , 8 1/2/" the only one that could work on the Alpine V 7 1/2" is the MG T series.

6 Cylinder

Studebaker

Avanti Champion Classic Commander Golden Hawk Hawk President Silver Hawk

1962-64 169" Engine Std. & O.D. 8 1/2 216 1 10

1946-60 169" Engine Std. 8 203 1 10

1958 185" Engine 8 1/2 216 1 10

1946-54 196" Engine 8 203 1 10

Austin

1954-62 A50, A55 8 203 1 10

Alfa Romeo

1978-88 Spider 2000cc 8 1/2 216 1 10

1972-76 Spider, Berlina, GTV 2000cc 8 1/2 216 1 10

1962-67 Duetto, Guilia, Sprint, Spider Voloce 1600cc 7 7/8 200 1 10

1965-67 Guilia GT, GTA 7 7/8 200 1 10

1956-62 Guilietta 7 7/8 200 1 10

Hillman

1962-64 Super Minx MK I & II 8 203 1 10

1958-64 Minx Ser. III, A, B, C 8 203 1 10

1954-59 Huskey Ser. I & II 7 1/4 184 1 10

1955-57 Mini MK 8, Ser. I & II 7 1/4 184 1 10

1948-54 Mini MK I-VII (Side Valve) 7 1/4 184 1 10

MG

Magnette

1954-61 Magnette ZB, ZA, MK III 8 203 1 10

MGA

1959-61 MGA 1600 (To Engine H3928) 8 203 1 10

TC TD TF

1951-53 Excl. TC, TF (To Engine 9409) 8 203 1 10

1947-51 TC, TF (From Engine 9409) 7 1/4 184 1 10

Range Rover

1966-79 2000 (From Engine Suffix G) 200TS (From Engine Suffix D) 8 1/2 216 1 10

Sunbeam

1965 Alpine Series IV 8 203 1 10

1963-64 Alpine Series III 8 203 1 10

1960-63 Alpine Series II, III 8 203 1 10

1958-61 Alpine Series I, Rapier Series II, III 8 203 1 10

Triumph

GT6

1966-73 MK I, II, III, Herald 12/50 8 1/2 216 1 10

Vitesse

1962-66 All 8 203 1 10

2000

1963-67 8 1/2 216 1 10

Volvo

122 Series

1967-68 1.8L (1783cc) w/B&B Clutch 8 1/2 216 1 10

1967-68 1.8L (1783cc) w/F&S Clutch 8 1/2 216 1 10

1962-66 1.8L (1783cc) B18 Engine 8 1/2 216 1 10

140 Series

1968-74 2.0L (1986cc) w/B&B Clutch 8 1/2 216 1 10

1968-74 2.0L (1986cc) w/F&S Clutch 8 1/2 216 1 10

1967-68 1.8L (1783cc) w/B&B Clutch 8 1/2 216 1 10

1967-68 1.8L (1783cc) w/F&S Clutch 8 1/2 216 1 10

1800 Series

1966-73 1.8L (1783cc) w/B&B Clutch 8 1/2 216 1 10

1966-73 1.8L (1783cc) w/F&S Clutch from chassis 21000 8 1/2 216 1 10

1965-66 1.8L (1783cc) Chassis 10500 to 20999 w/F&S Clutch 8 1/2 216 1 10

1962-65 1.8L (1783cc) w/B&B Clutch 8 1/2 216 1 10

544 Series

1962-65 1.8L (1783cc) B20 Engine 81/2 216 1 10

240 Series

1975-78 2.0L, 2.1L w/B&B Clutch 8 1/2 216 1 10

1975-78 2.0L, 2.1L w/F&S Clutch 8 1/2 216 1 10

jdoclogan

Platinum Level Sponsor

In order to replace the carbon ring affair something like that could be an option:

https://www.ebay.co.uk/itm/Made-in-...56c9430307:g:ae4AAOSwAB5dXGtQ&redirect=mobile

Great sleuthing Bernd.

However, Bob is correct about a roller release bearing. The problem is the original carbon release system has slight and yet continuous contact with the pressure plate component. That isn't a problem for the carbon setup. Albeit it wears out like a brake pad needing replaced. However, for the bearing replacement setup, while it is a good long use with no abuse (leaving foot on the clutch pedal)system, the continuous contact prematurely wears out the bearing. The answer is to put slight tension on the release bearing arm by fabricating a connection for a low pressure return spring. Of course this brings in the engineering design that allows for fine tuning adjustments to the spring load. I'm thinking a configuration with an eye bolt through a plate attached to the bearing release arm. A nut adjusting process with the spring looped through the eye of the bolt and anchored to a solid point.

Continued research and processing is needed.

husky drvr

Platinum Level Sponsor

Great sleuthing Bernd.

However, Bob is correct about a roller release bearing. The problem is the original carbon release system has slight and yet continuous contact with the pressure plate component. That isn't a problem for the carbon setup. Albeit it wears out like a brake pad needing replaced. However, for the bearing replacement setup, while it is a good long use with no abuse (leaving foot on the clutch pedal)system, the continuous contact prematurely wears out the bearing. The answer is to put slight tension on the release bearing arm by fabricating a connection for a low pressure return spring. Of course this brings in the engineering design that allows for fine tuning adjustments to the spring load. I'm thinking a configuration with an eye bolt through a plate attached to the bearing release arm. A nut adjusting process with the spring looped through the eye of the bolt and anchored to a solid point.

Continued research and processing is needed.

jdoclogan,

Actually, the problem lies in the design of the release bearing movement. The Rootes linkage moves the release bearing in an arc while all bearing type release units move coaxially with the trans input shaft and pressure plate. The Rootes arc causes the release unit to move laterally away from being coaxial. This would make the pressure plate fingers laterally shift out from a concentric alignment with the bearing face leading to difficulty rotating the bearing and sliding wear on the pressure plate fingers and bearing face.

jdoclogan

Platinum Level Sponsor

Doc,

true that could help. Doesn't the Tiger have something similar, i.e. a continuous pull back of the release arm via a tension spring ?

Yes, there is a spring system on the Tiger release bearing system - where I probably got the idea. Pretty straight forward without adjustment just a properly selected spring tension.

Last edited:

jdoclogan

Platinum Level Sponsor

jdoclogan,

Actually, the problem lies in the design of the release bearing movement. The Rootes linkage moves the release bearing in an arc while all bearing type release units move coaxially with the trans input shaft and pressure plate. The Rootes arc causes the release unit to move laterally away from being coaxial. This would make the pressure plate fingers laterally shift out from a concentric alignment with the bearing face leading to difficulty rotating the bearing and sliding wear on the pressure plate fingers and bearing face.

Don,

I had to go into the depths of my physics memory bank to process your statement. The arc issue and lateral dimension is eliminated when Rootes' engineers designed in the slightest contact with the carbon release bearing and the fingered components of the pressure plate. This eliminates any lateral movement when the bearing is continuously centered. Even when there is wear on the rotational points of the clutch arm (where the carbon component contacts the arm) and lateral movements may begin there is still a useful clutch release. If the roller bearing system were to be used having only 1 mm or 2mm clearance (thus not allowing for continuous motion and metal to metal wear of the bearing) it would minimize the lateral dimension or significantly reduce the issue to a non-issue when the self-centering dynamics almost immediately kick in.. There are some of these Alpine/MG release bearings that apparently have a Teflon rather than plastic surface (like the Green example in the above Ebay connection) on the contacting surface of the release bearing allowing for continuous contact. Apparently Teflon is that magnanimous that it can endure the frictional abrasion.

OK, now my eyes are rolling around like the thoughts in my head. I must stop thinking and writing.

Last edited:

spmdr

Diamond Level Sponsor

Just for the record, Tigers don't have a clutch "return spring" as standard equipment.

If found on a Tiger, it has been added, another subject.

Well, the biggest/first question for me is how many of the listed cars above use the carbon TOB?

The jump to a Non-carbon bearing is yet another subject.

AND, YUP, them new parts do look PURRDY.

So far, the clutch shop has not been too helpful in the world of interchange.

....They KEEP on bringing up how OLD this stuff is....

I can't wait to see them roll their eyes when I mention MG TC parts....

If found on a Tiger, it has been added, another subject.

Well, the biggest/first question for me is how many of the listed cars above use the carbon TOB?

The jump to a Non-carbon bearing is yet another subject.

AND, YUP, them new parts do look PURRDY.

So far, the clutch shop has not been too helpful in the world of interchange.

....They KEEP on bringing up how OLD this stuff is....

I can't wait to see them roll their eyes when I mention MG TC parts....

jdoclogan

Platinum Level Sponsor

Jan and Dan, you two have a great sense of humor.

Interesting about the return spring on the Tiger clutch. Not to divert this thread to that topic but I am curious about that return spring's purpose. I replaced the clutch in my Tiger years ago and just put everything back the way I dismantled it.

What do you two or anyone else think about an Alpine roller release bearing being directly used with the TTV pressure plate's diaphragm spring as seen in this thread's earlier photo?

Interesting about the return spring on the Tiger clutch. Not to divert this thread to that topic but I am curious about that return spring's purpose. I replaced the clutch in my Tiger years ago and just put everything back the way I dismantled it.

What do you two or anyone else think about an Alpine roller release bearing being directly used with the TTV pressure plate's diaphragm spring as seen in this thread's earlier photo?

Jerry,

I didn't follow how you concluded the throw out bearing remains centered against the pressure plate as it travels in its arc motion. I considered switching to a roller bearing when I swapped in an overdrive transmission. However, when I looked at how the lateral position of the bearing changes as it travels from not engaged through engagement, I concluded the roller bearing would get trashed in short order due to not always being centered against the pressure plate.

Mike

I didn't follow how you concluded the throw out bearing remains centered against the pressure plate as it travels in its arc motion. I considered switching to a roller bearing when I swapped in an overdrive transmission. However, when I looked at how the lateral position of the bearing changes as it travels from not engaged through engagement, I concluded the roller bearing would get trashed in short order due to not always being centered against the pressure plate.

Mike