Jay Laifman

Donation Time

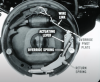

FWIW, I came up with a plan of sorts to provide a different spring to help improve the self adjusting brakes. This is just a rough idea. Here is video of how it works and shows what NEEDS to happen to make it work - the lever needs to go back and down. The Alpine has the spring which stops working after a while. The MGC and the TR GT6 MkIII have nothing. So super bad for them.

Rough picture. But it's to help explain. The sketch on the left is a red line and green line and circle. The red line is a bolt through the adjusting arm. The green line is an attached rod or cable going away from your view and through the backing plate - the green circle is the hole through the backing plate.

The sketch on the right is the side view. The red and green are the same parts. The black line is the backing plate. The yellow squiggle is a spring.

so when the parking brake lever is pulled up, as normal, it pulls the end of the adjusting arm which pushes the other end up (the end that shows in the picture). This then pulls the green rod or cable up, compressing the spring. Then when the parking brake is released, the spring I have pulls the arm back down.

And if it is positioned right, it will make sure the arm comes in enough to catch the next star.

Rough picture. But it's to help explain. The sketch on the left is a red line and green line and circle. The red line is a bolt through the adjusting arm. The green line is an attached rod or cable going away from your view and through the backing plate - the green circle is the hole through the backing plate.

The sketch on the right is the side view. The red and green are the same parts. The black line is the backing plate. The yellow squiggle is a spring.

so when the parking brake lever is pulled up, as normal, it pulls the end of the adjusting arm which pushes the other end up (the end that shows in the picture). This then pulls the green rod or cable up, compressing the spring. Then when the parking brake is released, the spring I have pulls the arm back down.

And if it is positioned right, it will make sure the arm comes in enough to catch the next star.