I have pulled the engine & trans out.

I have unbolted the trans from the engine.

What are the next steps to remove the clutch & other components from the rear of the engine?

It is probably quite simple, but reading the shop manual with its terminology is not sinking in.

Thank you for any help & guidance!

And if anyone knows a mentor in the Southern California area; I will certainly need one!

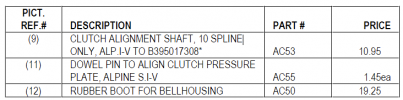

I will need to deliver the trans and clutch components to someone (or a shop) to go through.

Thanks!

I have unbolted the trans from the engine.

What are the next steps to remove the clutch & other components from the rear of the engine?

It is probably quite simple, but reading the shop manual with its terminology is not sinking in.

Thank you for any help & guidance!

And if anyone knows a mentor in the Southern California area; I will certainly need one!

I will need to deliver the trans and clutch components to someone (or a shop) to go through.

Thanks!